What Is Solder Tinning Flux . As with most things related to soldering, that begins with wetting forces. When solder flows over a surface like a component lead, it is said to “wet” the surface. Web given a choice between standard and tinning flux, which of the two would you pick up for your soldering job? Solder flow is called wetting. Web flux is another crucial ingredient in the recipe to success as it plays a vital role in preparing the electronic components and surface of the pcb, making solder flow. Web what soldering flux does. Understanding flux requires comprehension of what it does. Let's explore how tinning flux. Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection.

from www.protoexpress.com

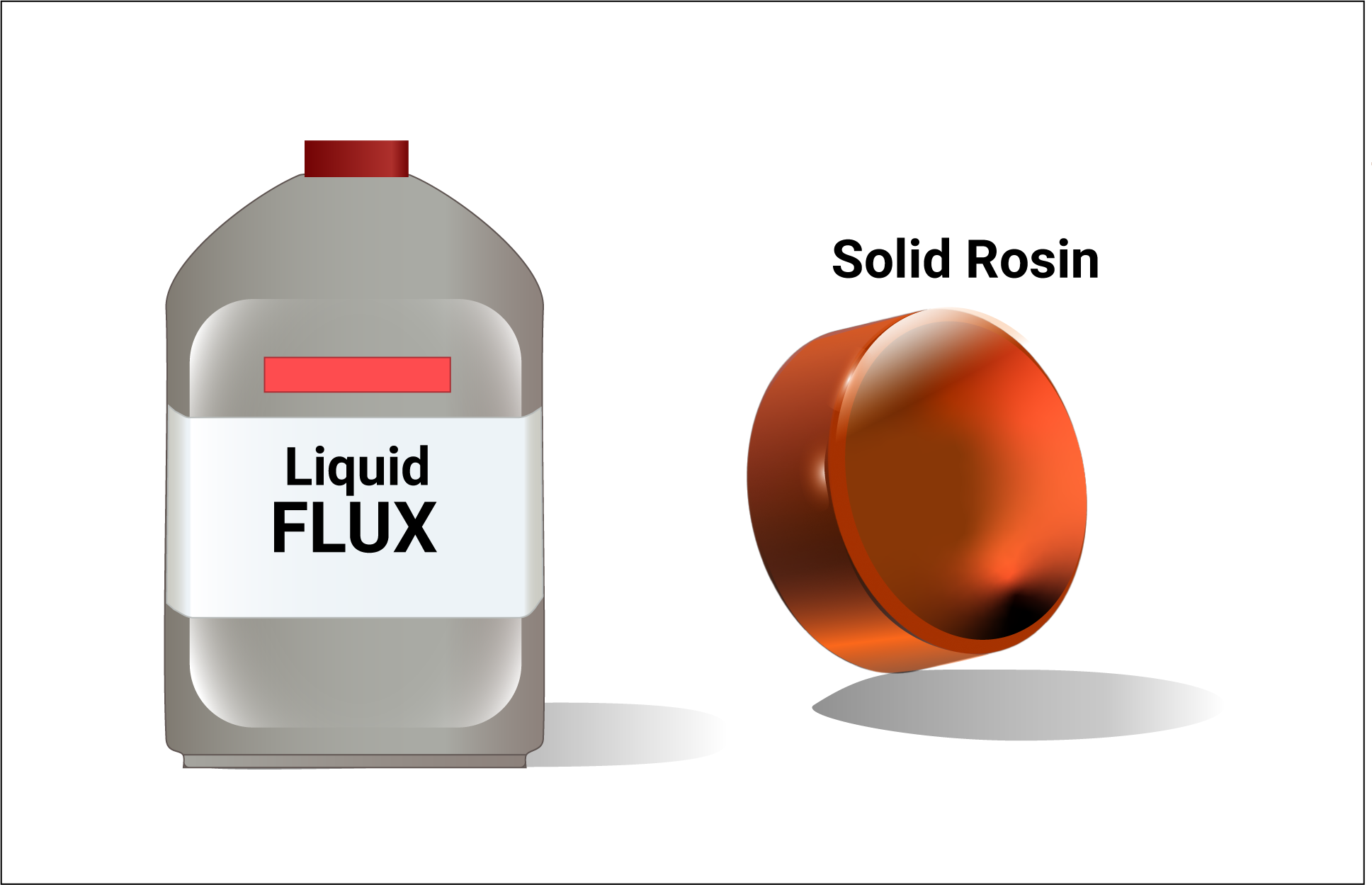

Understanding flux requires comprehension of what it does. When solder flows over a surface like a component lead, it is said to “wet” the surface. Solder flow is called wetting. Web given a choice between standard and tinning flux, which of the two would you pick up for your soldering job? Let's explore how tinning flux. Web what soldering flux does. As with most things related to soldering, that begins with wetting forces. Web flux is another crucial ingredient in the recipe to success as it plays a vital role in preparing the electronic components and surface of the pcb, making solder flow. Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection.

A Practical Guide to Soldering Flux Sierra Circuits

What Is Solder Tinning Flux Solder flow is called wetting. Solder flow is called wetting. Let's explore how tinning flux. Web flux is another crucial ingredient in the recipe to success as it plays a vital role in preparing the electronic components and surface of the pcb, making solder flow. When solder flows over a surface like a component lead, it is said to “wet” the surface. Understanding flux requires comprehension of what it does. Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection. As with most things related to soldering, that begins with wetting forces. Web given a choice between standard and tinning flux, which of the two would you pick up for your soldering job? Web what soldering flux does.

From www.homedepot.com

Oatey 8 oz. LeadFree Water Soluble Solder Tinning Flux 30142 The What Is Solder Tinning Flux Understanding flux requires comprehension of what it does. Solder flow is called wetting. Web given a choice between standard and tinning flux, which of the two would you pick up for your soldering job? Web what soldering flux does. When solder flows over a surface like a component lead, it is said to “wet” the surface. Web comparing tinning flux. What Is Solder Tinning Flux.

From blog.thepipingmart.com

Brazing Flux vs Soldering Flux What's the Difference What Is Solder Tinning Flux When solder flows over a surface like a component lead, it is said to “wet” the surface. Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection. Web given a choice between standard and tinning flux, which of the two would you pick up for your soldering job? Web. What Is Solder Tinning Flux.

From www.chemfaq.com

Soldering Flux What is it and How to Use It Chemical FAQ What Is Solder Tinning Flux When solder flows over a surface like a component lead, it is said to “wet” the surface. Understanding flux requires comprehension of what it does. As with most things related to soldering, that begins with wetting forces. Web flux is another crucial ingredient in the recipe to success as it plays a vital role in preparing the electronic components and. What Is Solder Tinning Flux.

From www.oatey.com

Oatey® No. 95 Tinning Flux Oatey What Is Solder Tinning Flux Solder flow is called wetting. Understanding flux requires comprehension of what it does. Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection. Let's explore how tinning flux. When solder flows over a surface like a component lead, it is said to “wet” the surface. Web flux is another. What Is Solder Tinning Flux.

From cesqjyyn.blob.core.windows.net

Flux Soldering Electronics at Ernesto Kates blog What Is Solder Tinning Flux Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection. Understanding flux requires comprehension of what it does. Solder flow is called wetting. Let's explore how tinning flux. Web given a choice between standard and tinning flux, which of the two would you pick up for your soldering job?. What Is Solder Tinning Flux.

From www.oatey.com

How to Expertly Solder LowLead Brass Using Tinning Flux Oatey What Is Solder Tinning Flux Web what soldering flux does. Let's explore how tinning flux. Understanding flux requires comprehension of what it does. Solder flow is called wetting. Web given a choice between standard and tinning flux, which of the two would you pick up for your soldering job? Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the. What Is Solder Tinning Flux.

From www.electronicsandyou.com

What is Solder Flux How to Use Flux in Soldering What Is Solder Tinning Flux Web given a choice between standard and tinning flux, which of the two would you pick up for your soldering job? Web flux is another crucial ingredient in the recipe to success as it plays a vital role in preparing the electronic components and surface of the pcb, making solder flow. When solder flows over a surface like a component. What Is Solder Tinning Flux.

From www.oatey.ca

How to Expertly Solder LowLead Brass Using Tinning Flux Oatey What Is Solder Tinning Flux Understanding flux requires comprehension of what it does. Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection. Solder flow is called wetting. Web what soldering flux does. As with most things related to soldering, that begins with wetting forces. Let's explore how tinning flux. When solder flows over. What Is Solder Tinning Flux.

From www.homedepot.com

Oatey 1.7 oz. LeadFree Water Soluble Solder Tinning Flux Paste 301402 What Is Solder Tinning Flux Solder flow is called wetting. When solder flows over a surface like a component lead, it is said to “wet” the surface. Web what soldering flux does. As with most things related to soldering, that begins with wetting forces. Let's explore how tinning flux. Web given a choice between standard and tinning flux, which of the two would you pick. What Is Solder Tinning Flux.

From www.oatey.com

How to Expertly Solder LowLead Brass Using Tinning Flux Oatey What Is Solder Tinning Flux Web flux is another crucial ingredient in the recipe to success as it plays a vital role in preparing the electronic components and surface of the pcb, making solder flow. As with most things related to soldering, that begins with wetting forces. Web what soldering flux does. Web given a choice between standard and tinning flux, which of the two. What Is Solder Tinning Flux.

From www.lowes.com

Oatey 1.7fl oz Tinning Soldering Flux at What Is Solder Tinning Flux As with most things related to soldering, that begins with wetting forces. Let's explore how tinning flux. Web what soldering flux does. Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection. Understanding flux requires comprehension of what it does. Web flux is another crucial ingredient in the recipe. What Is Solder Tinning Flux.

From www.aliexpress.com

Mcnuv50 Solder Paste Flux Soldering Tin Flux Electric Soldering Iron What Is Solder Tinning Flux As with most things related to soldering, that begins with wetting forces. Understanding flux requires comprehension of what it does. When solder flows over a surface like a component lead, it is said to “wet” the surface. Solder flow is called wetting. Web flux is another crucial ingredient in the recipe to success as it plays a vital role in. What Is Solder Tinning Flux.

From solderingironguide.com

How to Use Flux When Soldering Electronics For Beginners What Is Solder Tinning Flux Web what soldering flux does. Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection. As with most things related to soldering, that begins with wetting forces. Solder flow is called wetting. Understanding flux requires comprehension of what it does. Web flux is another crucial ingredient in the recipe. What Is Solder Tinning Flux.

From www.amazon.com

RadioShack Rosin Soldering Flux Paste, NonSpill Made in USA 2 oz What Is Solder Tinning Flux Let's explore how tinning flux. When solder flows over a surface like a component lead, it is said to “wet” the surface. Understanding flux requires comprehension of what it does. Web what soldering flux does. Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection. Solder flow is called. What Is Solder Tinning Flux.

From jhdpcb.com

Soldering Flux Guide In PCB Production Jhdpcb What Is Solder Tinning Flux Let's explore how tinning flux. Web flux is another crucial ingredient in the recipe to success as it plays a vital role in preparing the electronic components and surface of the pcb, making solder flow. As with most things related to soldering, that begins with wetting forces. Web given a choice between standard and tinning flux, which of the two. What Is Solder Tinning Flux.

From www.johnsonmfg.com

50/50 FLux`N`Solder What Is Solder Tinning Flux Let's explore how tinning flux. As with most things related to soldering, that begins with wetting forces. Web flux is another crucial ingredient in the recipe to success as it plays a vital role in preparing the electronic components and surface of the pcb, making solder flow. Web given a choice between standard and tinning flux, which of the two. What Is Solder Tinning Flux.

From www.youtube.com

What Is Flux? Soldering YouTube What Is Solder Tinning Flux Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection. Understanding flux requires comprehension of what it does. When solder flows over a surface like a component lead, it is said to “wet” the surface. Solder flow is called wetting. Web flux is another crucial ingredient in the recipe. What Is Solder Tinning Flux.

From www.homedepot.com

Oatey 1.7 oz. LeadFree Tinning Soldering Flux303742 The Home Depot What Is Solder Tinning Flux As with most things related to soldering, that begins with wetting forces. Let's explore how tinning flux. Web comparing tinning flux vs regular flux, while the standard type is strong and secure, the tinning flux provides added protection. Web given a choice between standard and tinning flux, which of the two would you pick up for your soldering job? Solder. What Is Solder Tinning Flux.